Insulation is the kind of material no one talks about when everything is fine—and everyone talks about when something goes wrong. A damp roof assembly, a cold slab, basement condensation, a cold room that never hits its energy target: once these issues appear, the question is no longer “What’s the cheapest board?” but “What will avoid the next complaint, claim, or repair?”

XPS is often reduced to a simple comparison of thermal conductivity, thickness, and price. In practice, results are driven by specifics: compressive strength that matches real loads, stability in wet conditions, thickness tolerances and warpage control, tight joints, and whether boards arrive flat and undamaged after transport. This article explains XPS in a practical way—what it is, where it performs best, where it should not be used, and how to specify it so delivered goods match both technical requirements and commercial expectations.

Ntroduction and the real problems XPS is meant to solve

Insulation is one of those materials people only notice when something goes wrong. In housing it shows up as rooms that never feel warm, heaters running all day, and cold corners that start “sweating” in winter. In commercial jobs it becomes a bigger issue: condensation on ceilings, dripping in cold areas, complaints about comfort, and higher operating costs that the owner did not plan for. A lot of these problems are not caused by “bad construction,” but by insulation that was chosen like a commodity—wrong grade, wrong thickness, wrong detailing for moisture, or boards that arrive inconsistent and create gaps during installation.

XPS is usually selected to reduce those headaches in places where water exposure and load are part of daily reality. When the insulation must keep its shape under pressure, stay stable in damp conditions, and still deliver predictable thermal performance, XPS tends to be a practical option.

What XPS insulation board is and why its structure matters

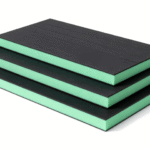

XPS is extruded polystyrene insulation board. It is made by an extrusion process that produces a uniform closed cell foam structure. That manufacturing route matters because it usually delivers a more consistent internal structure and surface skin, which helps with strength and moisture resistance in real use.

On the buying side, XPS is not “one product.” It comes in different thicknesses and strength grades, and those grades are the difference between a board that performs under a slab and one that slowly compresses and causes surface issues. You will also see different edge options. Square edge works, but shiplap/rabbet edges help reduce gaps at joints, which is one of the simplest ways to cut thermal bridging without changing the whole design.

The performance factors that decide success or failure

Thermal performance starts with thermal conductivity λ\lambdaλ and the R value you get from thickness. But what decides the result on site is often basic things: boards fitting tight, joints not left open, and the assembly not turning into a damp sponge. Even a strong insulation value on paper can be diluted by sloppy joints or water exposure in the wrong part of the build-up.

Compressive strength is the second “make or break” factor. Roofs, floors, under-slab, cold storage—these are not gentle environments. Loads can be long-term static (equipment, slab weight), rolling (forklifts), or point loads (racking legs). If the grade is under-specified, boards can indent, toppings crack, and flat roofs can develop low spots that hold water. That is why experienced buyers do not accept “standard grade” without matching it to load conditions.

Dimensional stability and tolerances are the quiet killers in large orders. If thickness varies, the surface becomes uneven and installers compensate by forcing boards into place, leaving gaps. If boards warp, the system looks fine on day one and then creates air pockets and thermal bridges. When people say “this insulation didn’t work,” it is often these practical issues, not the chemistry.

Where XPS works best

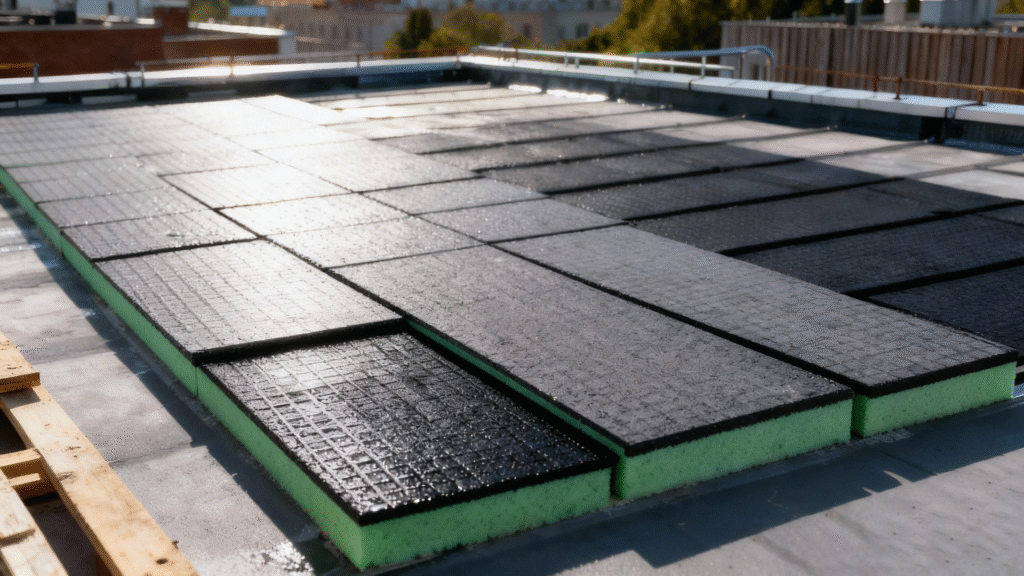

Flat roofs and inverted roof systems are classic XPS territory because the boards can handle compressive loads and are less sensitive to moisture than many other options. The important detail is protection: XPS should sit in a correctly designed roof build-up, not be left exposed to UV and weather. When that system is done properly, it helps reduce heat loss and improves roof performance over time.

Floors and under-slab insulation are another strong match. Ground slabs, garages, workshops, warehouses—these places benefit from insulation that does not crush under real use. A correct strength grade also helps avoid long-term deformation that can show up as cracked screeds or uneven finished floors.

Foundations and basements below grade often choose XPS because the environment is damp and insulation performance must stay stable. In these areas, it is common to pair XPS with waterproofing and drainage design. Insulation alone does not fix water problems, but it can support a durable system when used correctly.

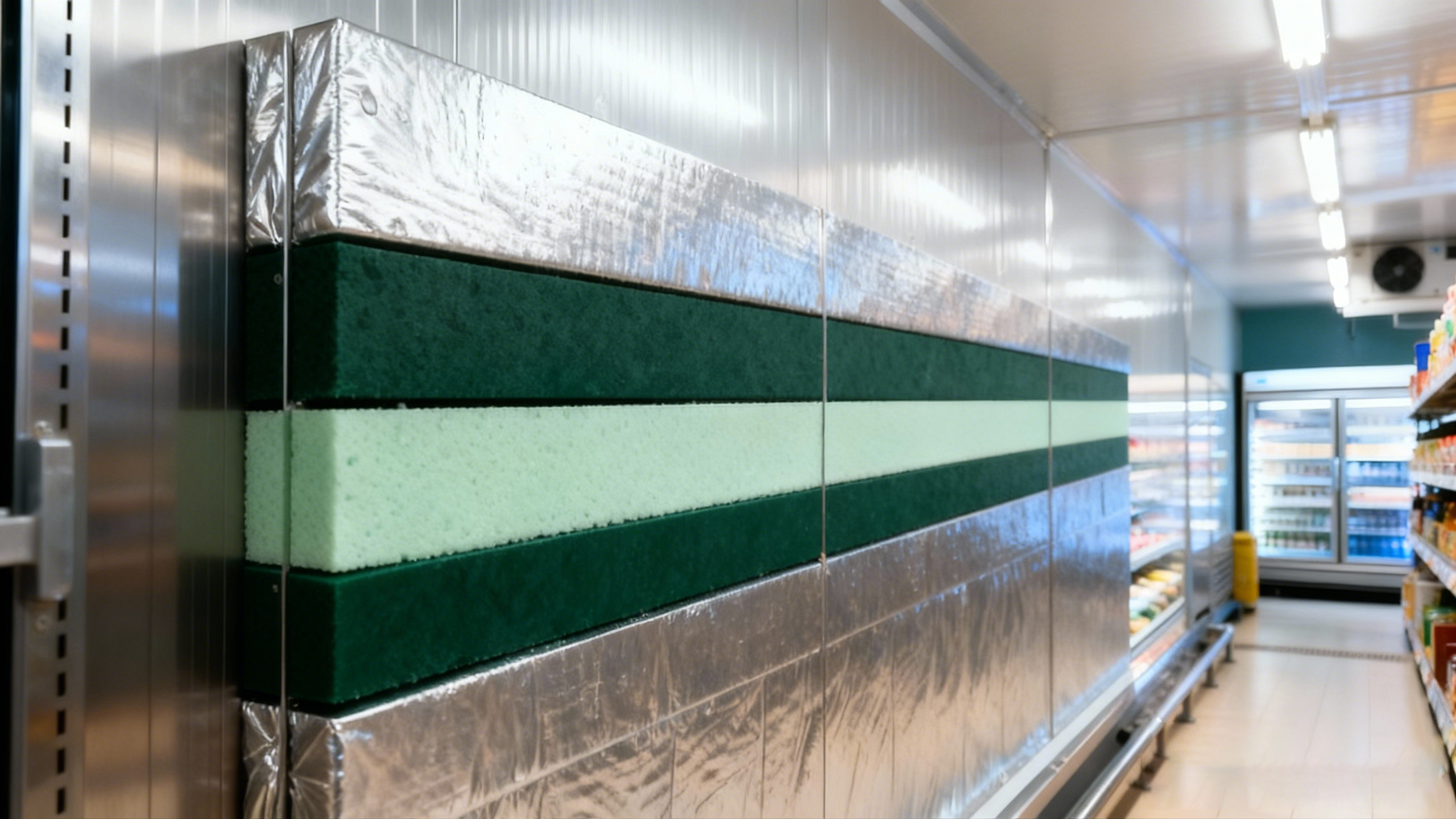

Cold rooms and refrigerated buildings also benefit from XPS when the design is focused on reducing heat gain and controlling condensation risk. In practice, joint treatment and vapor control are not “nice extras.” A cold room with unsealed joints will lose performance quickly and can create condensation lines that are hard to fix later.

Where XPS is not the right answer

XPS is not universal. In some projects, local building codes or fire strategies require non-combustible insulation in certain assemblies, and foam boards may be restricted or need additional protective layers. This is not optional—code requirements decide what can be used.

XPS may also be the wrong choice where the assembly needs higher vapor permeability for drying potential. In those designs, a different insulation approach can reduce moisture trapping risk depending on climate and wall build-up. And if the main goal is sound absorption, XPS is not usually the first choice; it is a thermal and load product more than an acoustic solution.

Leaving XPS exposed outdoors is another common mistake. UV and weathering will degrade the surface. If the design cannot protect it properly, it is better to choose a system that is meant to be exposed.

How to specify and buy XPS with less risk and who benefits most from working with a manufacturer

A clean specification follows a simple order. First define the application (roof, floor, under-slab, foundation, cold room). Then choose thickness for the target insulation level. Then choose compressive strength grade based on real loads. After that, lock down the details that prevent jobsite and import problems: thickness tolerance, board squareness, edge profile, packaging strength, pallet protection, labeling, and shipping method.

For compliance and credibility, buyers typically align products with recognized standards used in many markets, such as ASTM C578 and EN 13164, plus local building code and fire requirements. The point is not the document name—it is that properties are declared consistently and can be checked, not guessed.

The customers who usually benefit most from working directly with a real manufacturer are distributors who need stable SKUs and consistent repeat supply, importers who need export-grade packaging and reliable documentation, contractors who cannot afford warped boards and uneven thickness on fast schedules, and cold storage builders who need predictable performance and tight joints to control condensation and energy loss. In these partnerships, the “value” is not only price per board—it is fewer claims, fewer reworks, smoother installation, and repeatable quality across batches.

When sourcing XPS, the biggest risk is not choosing the “wrong brand”—it’s receiving product that cannot consistently deliver the specified performance across installation and repeat orders. Beyond λ\lambdaλ and thickness, focus on what drives outcomes on site: the correct compressive strength grade for actual loads (long-term static, rolling traffic, and point loads), dimensional stability, and tight tolerances so boards lay flat and joints close properly. Poor squareness, thickness variation, and warpage lead to gaps, thermal bridging, uneven surfaces, and eventual callbacks—regardless of what the datasheet claims.

XPS is often a strong choice for roofs, floors/under-slab, below-grade, and cold rooms because it handles moisture exposure and load better than many alternatives, but only when the assembly is detailed correctly and boards are protected from UV and weathering. From a procurement standpoint, prioritize suppliers that offer stable lead times and SKUs, export-ready packaging that reduces breakage, verifiable documentation aligned to ASTM C578/EN 13164 and local code needs, and batch traceability. The payoff is fewer disputes, fewer reworks, smoother installation, and repeatable quality—rather than short-term savings that turn into project cost.