One of the most frustrating site issues is when a material “looks fine” on delivery, but problems surface only after work has moved on. XPS warping is a classic example: boards can appear flat in the pack, feel manageable during installation, and then reveal lifted edges, opened joints, or an uneven plane after screeds, membranes, or finishes are in place. At that point, it’s no longer about replacing a few boards—it becomes a mix of rework, schedule pressure, added labor, and a difficult conversation about responsibility.

What makes warping harder is that it rarely has a single cause. Heat exposure, moisture handling, sustained loads, substrate flatness, and installation methods can all play a role, and a wrong diagnosis usually leads to the wrong “fix.” This article organizes the issue the way it happens on real projects: how to recognize the patterns, how to narrow down the likely cause, how to prevent repeat problems through clear specs and site controls, and how to document issues properly when a batch should be held or rejected.

What “warping” looks like on site and why it turns into real money

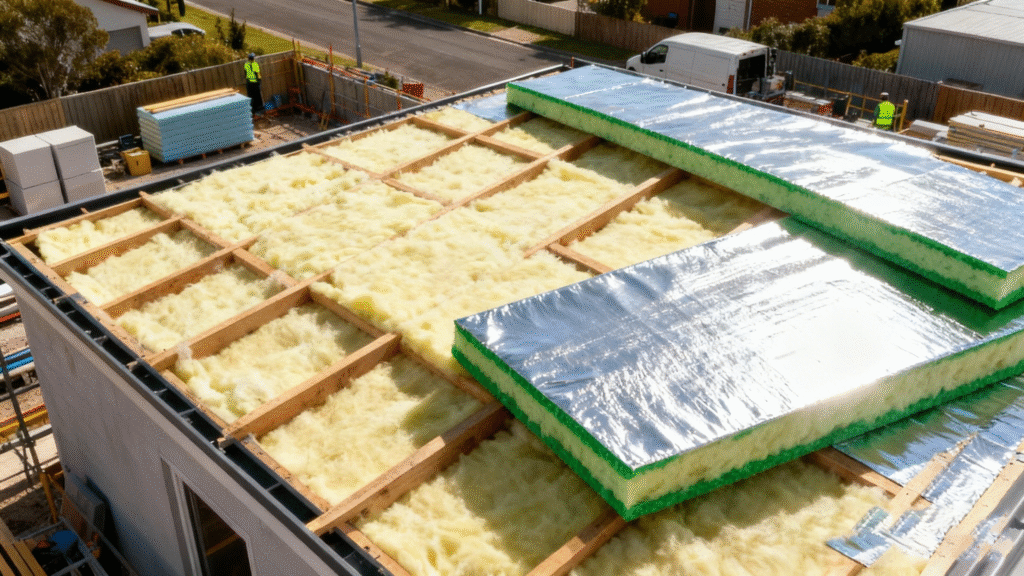

Warping in XPS usually shows up as bowing across the face, cupping at corners, twisting along the length, or edges that lift so the board “rocks” instead of sitting flat. The problem is not only appearance. Once joints open up, heat flows through those gaps and the insulation layer stops performing as designed. On walls that means cold spots and condensation risk; on roofs it can mean poor contact under membranes and protection layers; on floors it often shows up later as uneven finishes, cracked screeds, or hollow-sounding areas.

The expensive part is the chain reaction. Crews spend time sorting boards, adding extra adhesive or leveling compound, trimming edges, fighting alignment, and slowing down downstream trades. When finishes go on top, even small unevenness can telegraph through. By the time a project manager sees it, the discussion is no longer about insulation performance but about delays, rework, and who is responsible.

Does XPS insulation board warp over time the honest answer

A well-made XPS board that is correctly selected for the application, stored properly, and installed according to the system details is generally dimensionally stable in service. Most “over time” warping complaints don’t begin in year five; they begin in the first few days or weeks, then become visible only after finishing layers are installed or after loads are introduced.

It helps to separate three situations that often get mixed together. First is early deformation from heat during transport or staging, where boards look fine when banded but bow after unstacking. Second is load-related deformation, where the system slowly settles under sustained load because compressive strength was under-specified for the real conditions. Third is installation-amplified unevenness, where the boards may be within tolerance but the substrate, bonding method, or fastening pattern creates a surface that behaves like warped insulation.

A practical rule: if deformation appears mainly on boards that were exposed on top of a stack, it points to storage and heat; if it concentrates where heavy loads sit, it points to grade selection and load design; if it shows up as a “wavy” finished surface without clear board distortion, it points to installation and substrate flatness.

The causes behind most real-world warping cases

Heat exposure and temperature gradients are the most common trigger before installation. Pallets left in direct sun, dark wrapping heating up, roof staging on hot decks, and sealed containers during hot seasons can create uneven temperatures through the thickness of the board. When the board is restrained by strapping or stacked tight, internal stresses can build up and then release as bowing once packs are opened.

Moisture misuse is another frequent contributor. XPS is chosen partly because it has low water absorption, but “low absorption” does not mean “no risk.” Storing packs on wet ground, letting rain soak packaging, or allowing condensation to repeatedly wet and dry the surface can lead to fitment issues and uneven behavior during installation. Even if the foam core remains relatively dry, wet packaging and uneven site conditions often correlate with boards that don’t lie flat and joints that don’t close well.

Load selection is the cause that truly happens “over time.” Under floors, inverted roofs, cold-room slabs, and other assemblies with sustained loads, the XPS grade has to match not only average load but also point loads, load duration, and temperature conditions. When the compressive strength class is too low for the real job, long-term creep can create settlement that shows up as steps at joints, uneven finishes, and localized depressions that get blamed as “warping.”

Installation choices can turn small tolerances into visible problems. Uneven substrates, spot-bonding where continuous support is needed, inconsistent mechanical fixing, and failing to stagger joints can all create a surface that looks like the insulation is warped even when the material is within dimensional tolerance.

Where it happens most often and how to diagnose the pattern quickly

Roofs are a high-risk zone because the staging habit is convenient and common. Boards often sit exposed for hours or days before waterproofing, protection layers, or ballast go on. Sun, wind, and deck temperature swings can create exactly the gradient that leads to bowing. Inverted roofs add another layer of sensitivity because the insulation interacts with water management and protection details, so gaps and rocking boards quickly become system issues.

Floors are another hotspot, especially on commercial and industrial projects where the insulation becomes a temporary working platform. Repeated foot traffic, pallet staging, equipment wheels, and stacked materials introduce point loads long before the final screed or slab is placed. If the compressive strength grade was selected without considering construction-phase loads, deformation can start early and then become permanent once covered.

Cold storage and temperature-cycling environments demand tighter discipline because temperature gradients are routine and joint quality matters more. Assemblies that cycle between warm and cold conditions punish sloppy detailing. In these projects, the “small issues” like edge support, tight seams, and quick covering are what protect the insulation layer’s performance.

A quick field diagnosis that saves time is to look at distribution. Top-of-stack deformation suggests sun and storage heat. Localized deformation under equipment legs or along traffic paths suggests point loads and grade mismatch. Batch-wide uniform issues across many packs suggest a logistics heat event or a production consistency issue that should be addressed immediately before more material is installed.

Prevention that procurement and crews can execute without guesswork

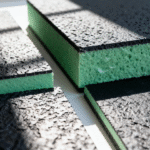

Prevention starts with writing the purchase specification in a way that matches the assembly. State the application clearly, define the required compressive strength class for the load scenario, and agree on how flatness or warpage will be checked at delivery. Using recognized reference frameworks reduces disputes; many specs are aligned to standards such as ASTM C578 (rigid polystyrene thermal insulation) and EN 13164 (factory-made XPS products). The main benefit is not the document name—it’s that acceptance criteria become measurable rather than subjective.

Then lock down the storage rules that prevent most complaints. Keep pallets flat with full support so packs don’t bridge over uneven ground. Keep packs shaded where possible and avoid long exposure in direct sun, especially for the top packs. Don’t leave boards in sealed “heat trap” conditions longer than necessary. Keep insulation away from standing water and do not store packs directly on wet soil. On roofs, limit exposure time; if boards must be staged, cover them and move them into the assembly quickly.

Installation discipline matters just as much. Substrate flatness is non-negotiable; if the base is uneven, the insulation layer will reflect that. Follow the system’s adhesive coverage requirements so boards are supported evenly. If mechanical fixing is part of the system, keep fastener layout consistent and adequate. Stagger joints to avoid continuous seam lines, and close joints properly to reduce thermal bridging. The goal is simple: keep the insulation layer flat, supported, and quickly protected.

What to do when boards are warped on site and when to reject them

Mild bowing that appears after heat exposure can often be reduced with basic handling. Restack boards on a truly flat surface, apply even weight across the stack, keep them shaded, and allow time for the material to relax before installation. When the schedule is tight, slightly affected boards can be redirected into cut pieces or smaller infill areas where the system allows and where joint tightness and flatness can still be controlled.

Severe deformation should not be “solved” by adding excessive adhesive thickness across large areas. That approach often increases cost, creates curing and leveling issues, and shifts the defect into the next layer. On roofs and high-load floors, forcing severely bowed boards into place is especially risky because it invites gaps, rocking points, and long-term performance problems.

Reject and document when the warpage exceeds the agreed criteria, when the majority of a batch shows the same distortion, or when boards cannot sit flat without force. Documentation should be straightforward and factual: photos of pallet condition and packaging, batch/lot identifiers, simple straightedge measurements with recorded gaps, and notes on storage conditions from arrival to installation. That record is what makes resolution possible—whether the cause is a heat event in logistics, handling on site, or a product consistency issue.

As a manufacturer, the most reliable projects are the ones where the buyer shares the application and load scenario early, the grade is selected accordingly, and storage/installation rules are treated as part of the insulation system rather than optional handling advice. That’s where XPS delivers its value: stable insulation performance, fewer callbacks, and smoother installation with predictable results.

From a procurement standpoint, XPS warping is rarely just a “material appearance” issue—it’s a predictability problem. Once boards don’t sit flat, crews lose time sorting and compensating, joints open and performance drops, and downstream layers inherit unevenness that can turn into call-backs. The commercial impact is usually larger than the value of the affected boards: added labor, extra adhesive or leveling, schedule drift, and, in the worst cases, disputes over who owns the cost.

Reliable suppliers reduce that risk in three ways. First, they make product selection clear for the actual application—especially compressive strength class for sustained loads and point loads, and dimensional stability expectations. Second, they deliver consistently: packaging, pallet support, and logistics practices that minimize heat exposure and moisture handling issues, plus a straightforward incoming inspection method with agreed acceptance criteria. Third, they support resolution when something goes wrong: traceable batch information, objective measurements, and practical guidance on what can be recovered on site versus what should be quarantined or rejected.

The key takeaway is simple: quality XPS is generally stable when the grade matches the job and handling is controlled. Most warping can be prevented by writing workable specs, enforcing storage and staging rules, and installing on a flat, fully supported base—turning a common headache into a manageable process.